Sa Plate Enveloping and Stacking process ay binabalutan ng separator ang isa sa positive o negative na plaka bago sila salitang pagpatungin at ibungkos batay sa dami ng plaka na kailangang ilagay sa bawat cell ng battery container

(30% complete)

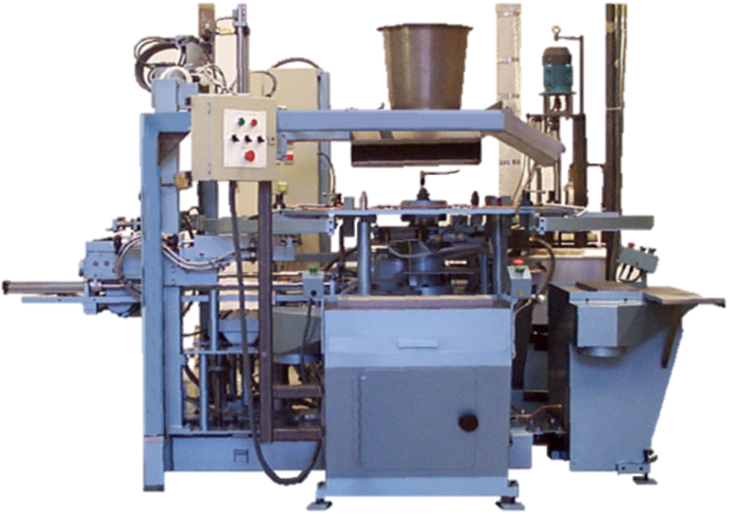

The Cast On Strap machine is used to form the strap that connects the lugs of the plates in series. It uses a heated mold with cavities where molten lead is pumped. The lugs are dipped into the cavities with molten lead then allowed to cool. Once ejected, the lugs are now connected through the strap. You can learn more by enrolling to this course.

The Inter Cell Welding Machine is used to fuse the tabs on the strap to connect the grouped elements in each cell through the partition holes. It uses two Jaw electrodes to squeeze the lead tabs into the partition hole then apply resistance welding to melt the lead and cause fusion. You may enroll to this course if you want to learn more about Machine Operation, Maintenance, Setup, & Troubleshooting.

(25% Complete)

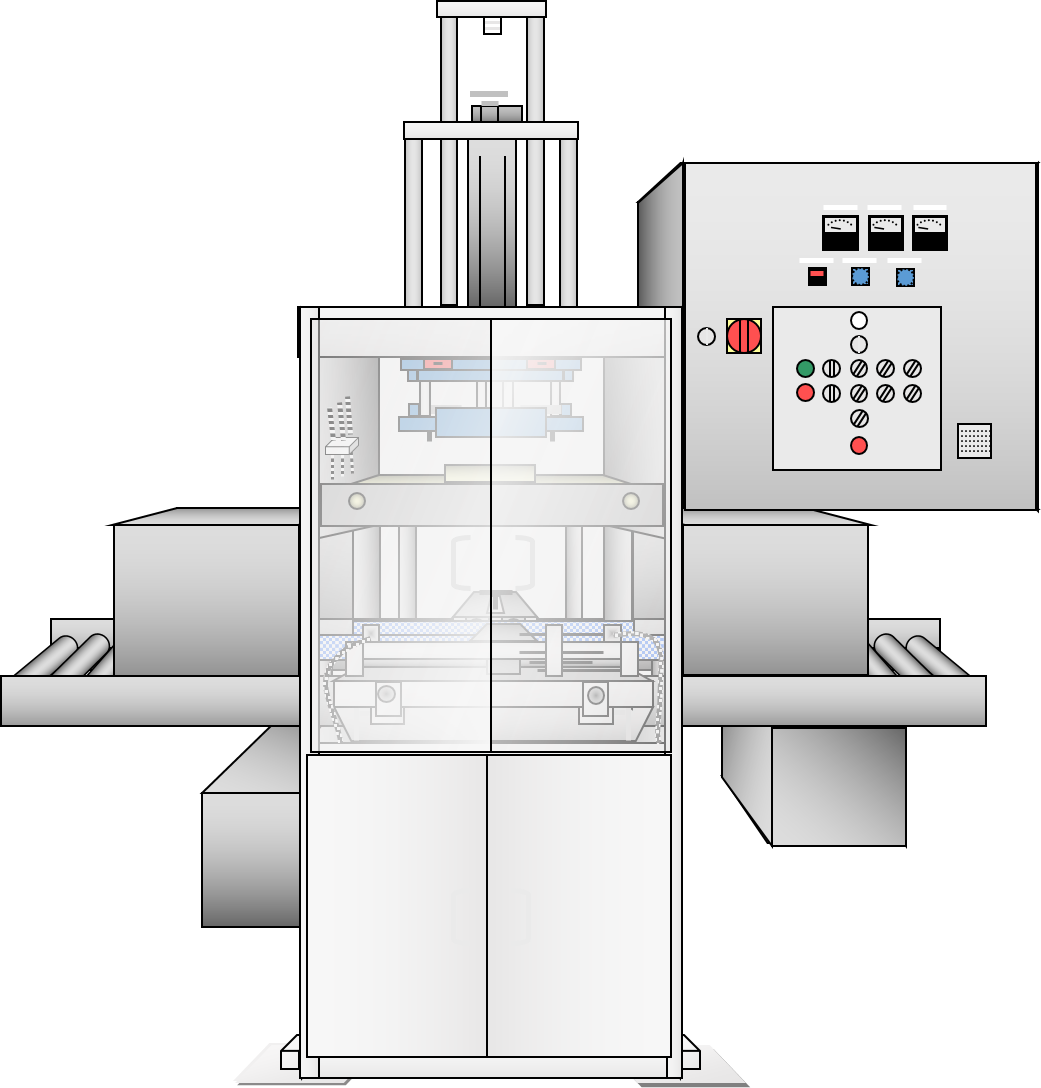

The Lid Sealing Machine is used to seal the Lid (or Primary Cover) to the container. It uses heat fusion through a hotplate which melts the seal zones on the cover and the container then presses them together allowing the molten plastic to fuse and cooldown. You may enroll in this course to learn more about Machine Operation, Maintenance, Setup, and Troubleshooting.

(25% Complete)